We are using AI

to advance science and engineering,

and create value for all

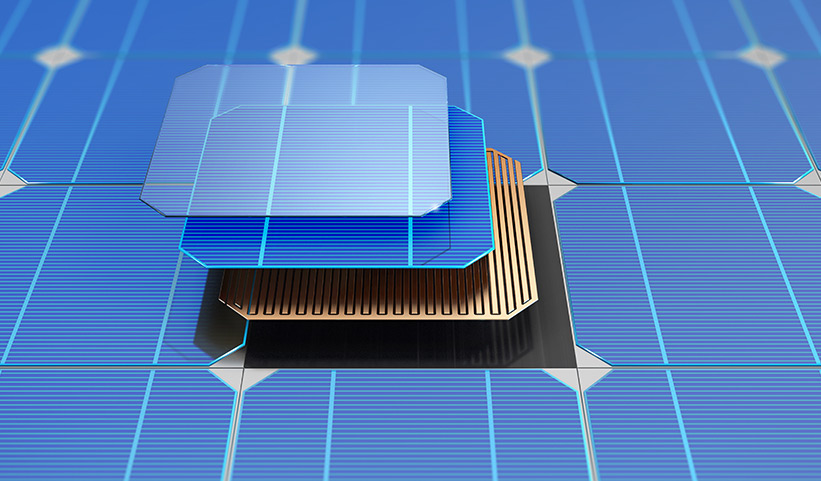

Technology

An engine for dealing with complexity

Applications

Expanding the limits

of AI

Careers

A positive work environment to thrive